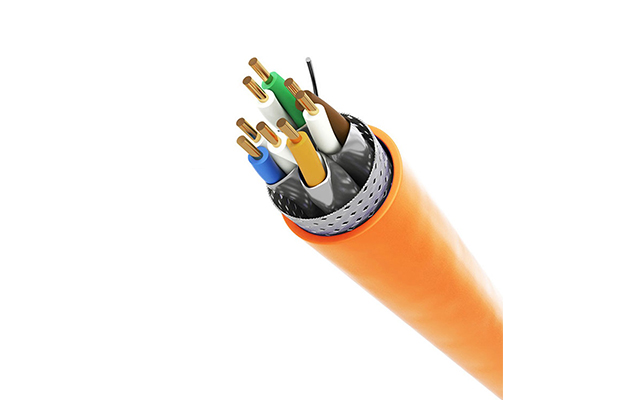

Construction

Solid bare copper conductors insulated with thermoplastics polyolefin. Two insulated conductors twisted together to form a pair and four such pairs cabled to form the basic unit. A cross filler is cabled in between to separate the 4 pairs insulated conductors . Aluminum Polyester Tape and tinned copper braiding overall the 4pairs .Overall jacket with PVC, LSZH, PE compound.

Standard Compliances

ISO/IEC 11801:2011(Ed.2.2)

IEC 61156-5:2009(Ed.2.0)

EN 50173-1:2011

EN 50173-2:2007 including amendment A1:2010

ANSI/TIA-568-C.2:2009

Applications

IEEE 802.3: 1000BASE-T (Gigabit Ethernet), 100BASE-TX, 10BASE-T

ANSI/TIA/EIA-854: 1000BASE-TX

155 Mb/s, 1.2 Gb/s ATM

ANSI X3.263: 100 Mb/s

IEEE 802.3af DTE Power (POE)

4/16 Mb/s Token Ring

Digital Video

Broadband and Baseband Analog Video

Cable Description

| Conductor |

| Size |

24 AWG |

| Type |

Solid bare copper |

| Diameter (mm) |

0.55± 0.01 |

| Insulation |

| Type |

PE |

| Diameter (mm) |

1.13± 0.05 |

| Min. thickness (mm) |

0.26 |

| Pairs with color code |

| Pair 1 |

Blue / White – blue strip |

| Pair 2 |

Orange / White – orange strip |

| Pair 3 |

Green / White – green strip |

| Pair 4 |

Brown / White – brown strip |

| Central Element |

| Type |

PE cross separator |

| Jacket |

| Type |

PVC, LSZH, PE |

| Overall Diameter (mm) |

7.29 ± 0.3 |

| Shield |

| TPYE (Overall shielded) |

Polyester Tape |

| TPYE (Overall shielded) |

Aluminum Polyester Tape |

| Tinned copper drain wire(mm) |

0.495 ± 0.008 |

| Type (Overall braiding) |

Tinned Copper 40% to 60% Braiding |

| Cold bend test |

-20 ± 2℃ X 4hrs no. crack |

| Dielectric strength |

AC 1.7 KV for 2S. |

| Insulation |

Before Aging |

After aging |

| Min. Tension strength (psi) |

2400 |

75% before aging (100℃ X 48hrs) |

| Min elongation (%) |

300 |

75% before aging (100℃ X 48hrs) |

| Jacket |

|

|

| Min. Tension strength (psi) |

2000 |

75% before aging (100℃ X 168hrs) |

| Min elongation (%) |

100 |

50% before aging (100℃ X 168hrs) |

| Min. bending radius (mm) |

60 |

| Max. pulling tension (Ibs) |

25 |

| Installation temperature |

-10℃ to +60℃ |

| Operating temperature |

-10℃ to +60℃ |

Technical Data- Physical

Technical Data – Electrical

| Conductor resistance (Ω/100m @ 20℃) |

Max. |

9.5 |

| DC resistance unbalance (%) |

Max. |

4 |

| Pair-to-ground capacitance unbalance (pF/km) |

Max. |

1600 |

| Delay skew (ns/100m) |

Max. |

45 |

4 ≦ f ≦ 250MHz |

| Insertion Loss (dB/100m) |

Max. |

1.82*√f + 0.0169* f +0.25/√f |

4 ≦ f ≦ 250MHz |

| Pair to Pair NEXT (dB/100m) |

Min. |

75.3 – 15 * log(f) |

4 ≦ f ≦ 250MHz |

| PowerSum pr-pr NEXT (dB/100m) |

Min. |

72.3 – 15 * log(f) |

4 ≦ f ≦ 250MHz |

| ELFEXT (dB/100m) |

Min. |

68 – 20 * log(f) |

4 ≦ f ≦ 250MHz |

| PowerSum ELFEXT (dB/100m) |

Min. |

65 – 20 * log(f) |

4 ≦ f ≦ 250MHz |

| Return Loss (dB) |

Min. |

20 + 5 * log(f) |

1 ≦ f <10MHz |

|

|

25 |

10 ≦ f <20MHz |

|

|

25 – 7 * log(f / 20) |

20 ≦ f ≦250MHz |

| Propagation Delay (ns/100m) |

Max. |

534 + 36 /√f |

4 ≦ f ≦ 250MHz |

| Input Impedance (Ω) |

|

100 ± 15% |

1 ≦ f ≦ 100MHz |

|

|

100 ± 22% |

100<f≦ 250MHz |

| IEC 61156-5 ed2.0 Category 6 horizontal cable parameters |

|

Freq.

(MHz)

|

Ins. Loss

(dB/100m) |

RL

(dB) |

Pair to Pair |

Power Sum |

Po. Delay

(ns/100) |

| NEXT |

ELFEXT |

NEXT |

ELFEXT |

| (dB/100m) |

(dB/100m) |

|

Max. |

Min. |

Min. |

Min. |

Min. |

Min. |

Max. |

| 1 |

— |

20 |

— |

— |

— |

— |

— |

| 4 |

3.8 |

23 |

66.3 |

56.0 |

63.3 |

53.0 |

552.0 |

| 10 |

6.0 |

25 |

60.3 |

48.0 |

57.3 |

45.0 |

545.4 |

| 16 |

7.6 |

25 |

57.2 |

43.9 |

54.2 |

40.9 |

543.0 |

| 20 |

8.5 |

25 |

55.8 |

42.0 |

52.8 |

39.0 |

542.0 |

| 31.25 |

10.7 |

23.6 |

52.9 |

38.1 |

49.9 |

35.1 |

540.4 |

| 62.5 |

15.5 |

21.5 |

48.4 |

32.1 |

45.4 |

29.1 |

538.6 |

| 100 |

19.9 |

20.1 |

45.3 |

28.0 |

42.3 |

25.0 |

537.6 |

| 200 |

29.1 |

18 |

40.8 |

22.0 |

37.8 |

19.0 |

536.5 |

| 250 |

33.0 |

17.3 |

39.3 |

20.0 |

36.3 |

17.0 |

536.3 |

Note

All electrical characteristics are given at 20℃

All tests include 401 points swept frequency measurements.